DN4800 Battery packs gantry spot welding machine

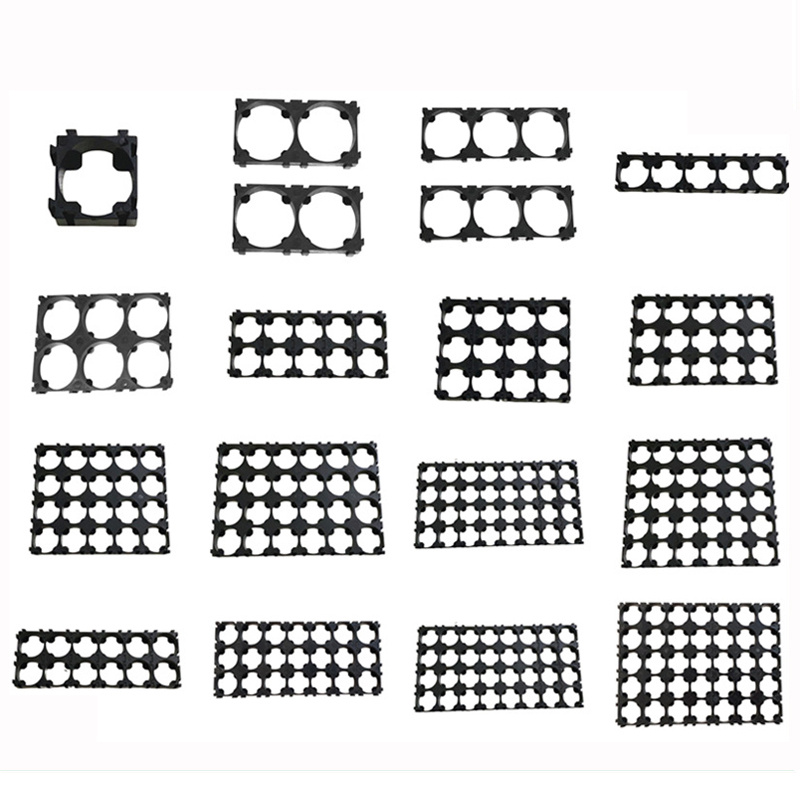

- Welding of metal sheets for 18650, 21700, and 32700 battery packs

- Welding thickness 0.1-0.2mm

- 24 hours of continuous high-speed welding(No false soldering, no excessive soldering)

- Precision microcomputer control, parameters can be changed

- Gantry structure design,more stable operation,height adjustable(Suitable for welding large battery packs)

DN4800 Main parameters

Input voltage | Single phase 220V±10% 50/60Hz |

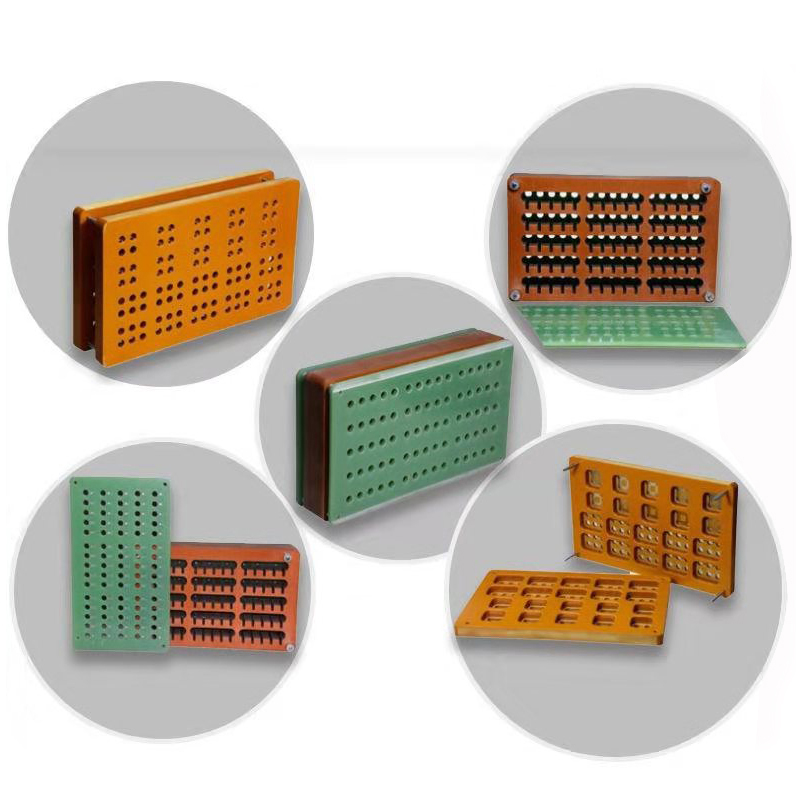

Welding method | Single-sided double-point balanced welding |

Drive mode | Cylinder type welded pressurized head |

Pressure | 0.4~0.8MPa |

Pressure range | 1.5~5kgf |

Pressurization method | Spring + Pneumatic |

Secondary spring pressurization | 1~10kgf |

Max. cylinder stroke | 15mm,Default by 10mm |

Max. workpiece height | 130mm |

Max. workpiece size | Width 325mm, length determined by workbench |

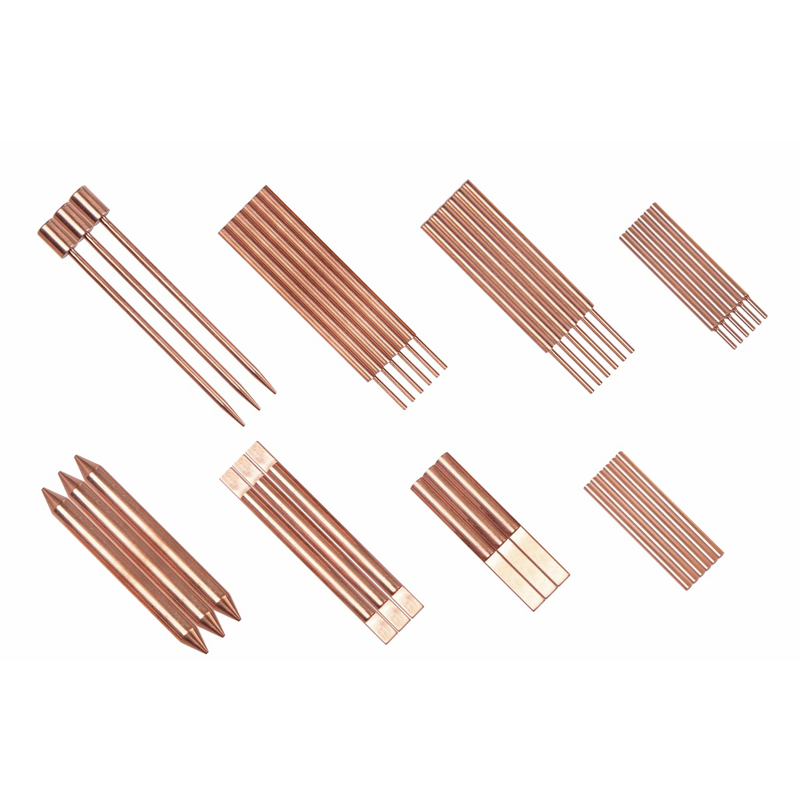

Electrodes | φ3.0mm(Imported alumina copper) |

Operating frequency | About 160 times/minute |

Size(mm) | 650×335×380(Excluding tables) |

Weight | 30kg |

DN4800 Precision spot welding power supply

Psesf, energy, and preloading time can be freely changed and Multi pulse precision adjustment.

Improve the waveform of welding output energy, enhancewelding ability, and make the welding points firm and beautiful.

Automatic voltage monitoring, tracking and compensationPneumatic double electrode precision welding machine head.

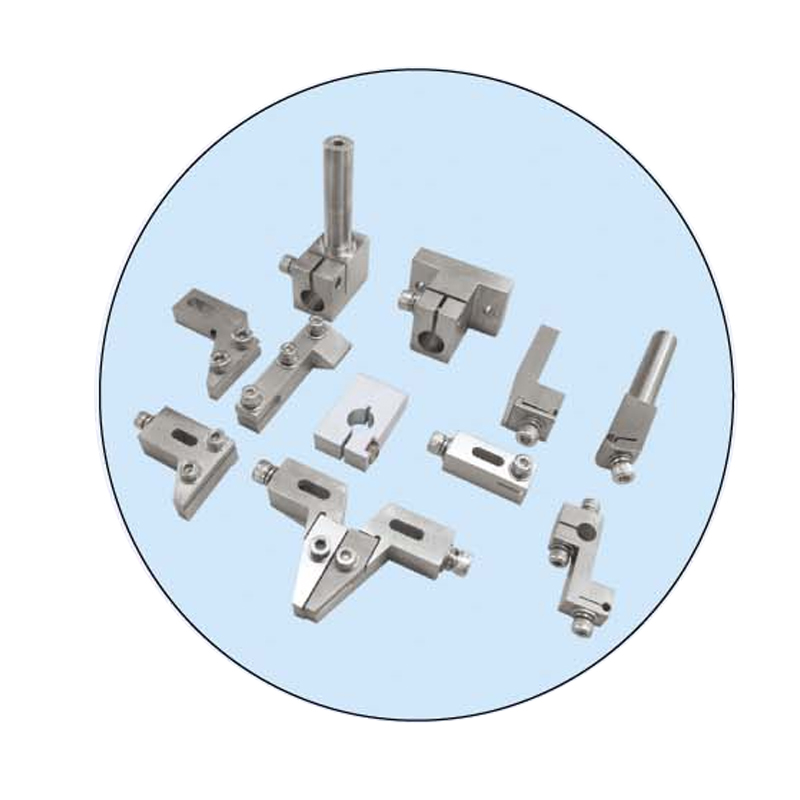

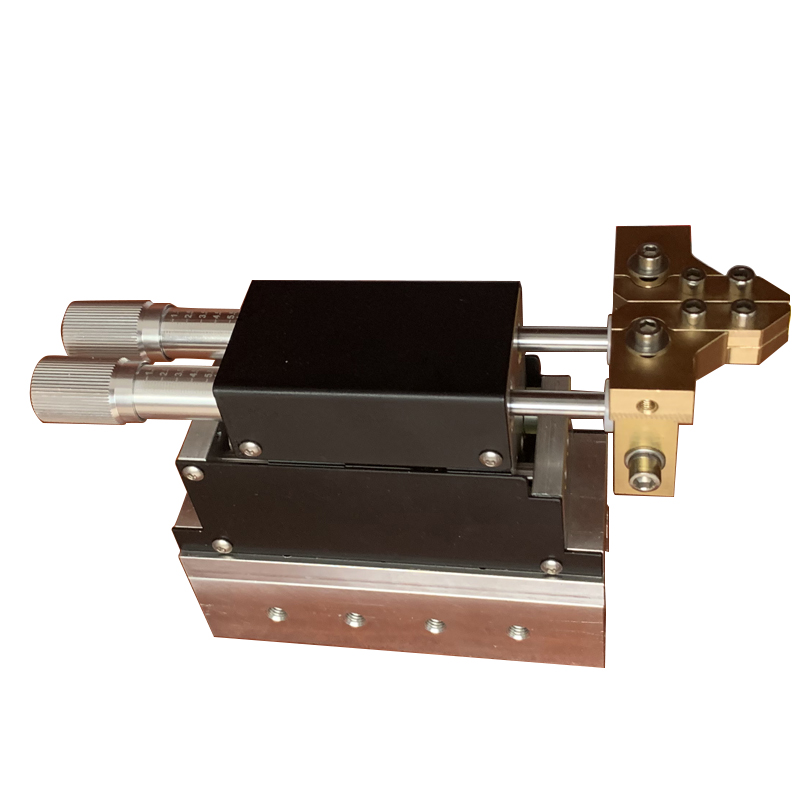

High precision parallel battery packs spot welding heads

High precision dual axis pressurized follow-upmechanism, achieving precision welding.

Height adjustable, 6-130mm.

High precision parallel battery packs spot weldingheads,soft and stable welding pressure.