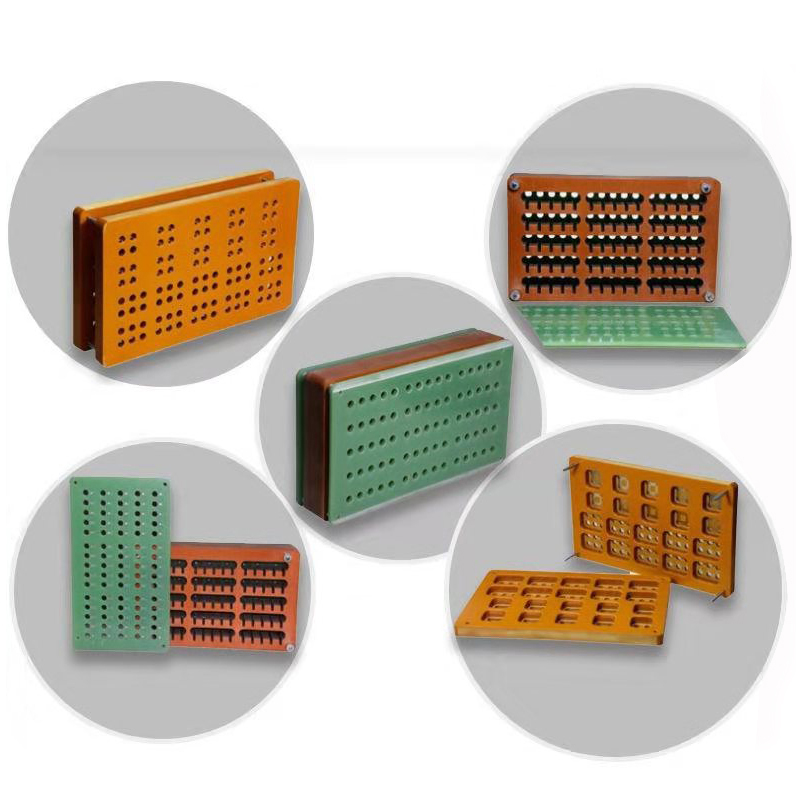

Working stroke 200 * 280 * (50-150mm)

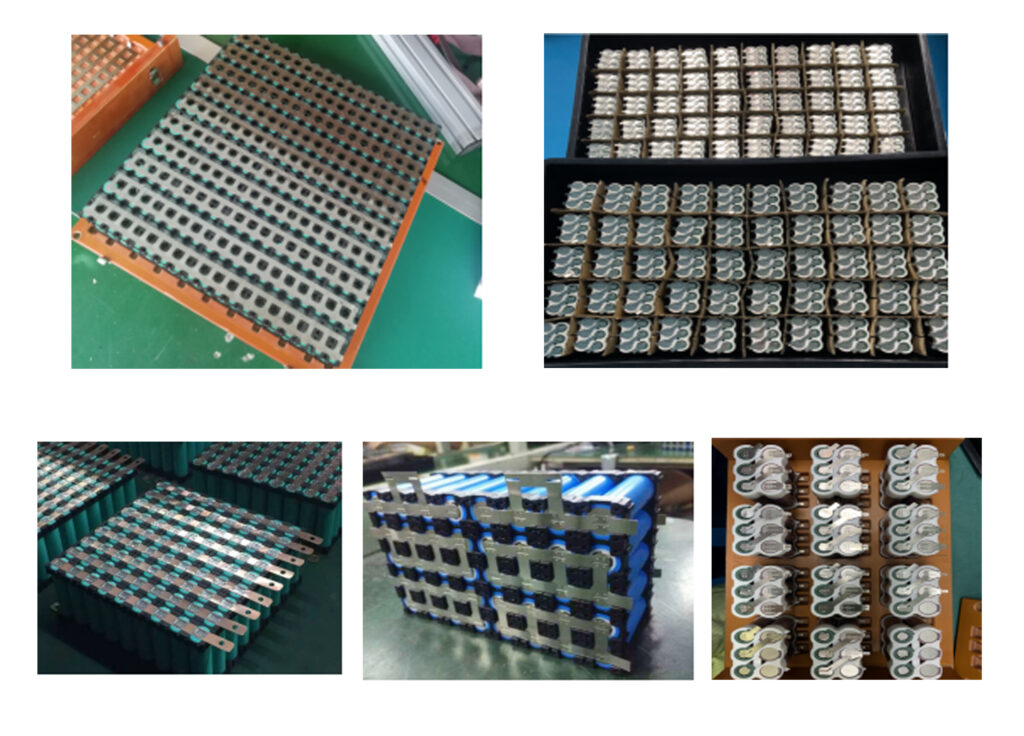

Welding 0.1~0.35mm

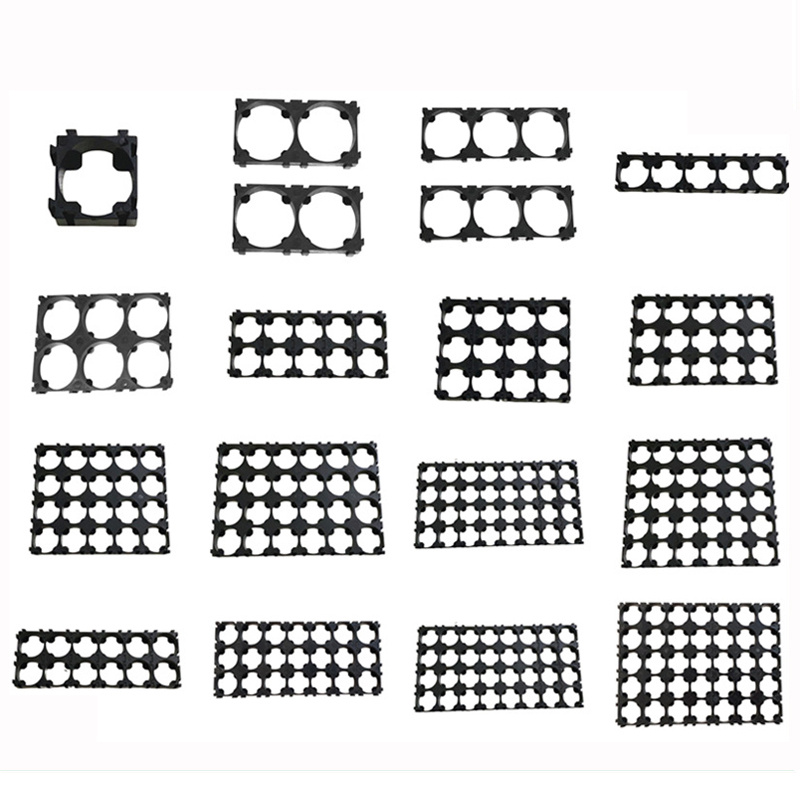

Double station can be worked alternately

Welding efficiency 2000PCS/H

Welding of cylindrical cell power battery pack

Can be configured with different welding power sources

Main parameters

| Machining stroke | X 0~200mm,Y 0~280mm |

| Max welding speed | 0.6s/spot,2000pcs/h,It varies depending on the welding power source |

| Max welding thickness | 0.3mm |

| Welding count | Support |

| Power supply | 220V 50/60Hz |

| Power consumption | 0.6kW during busy hours and 0.1kW during idle hours |

| Power Capacity | 1.2kW(including power supply) |

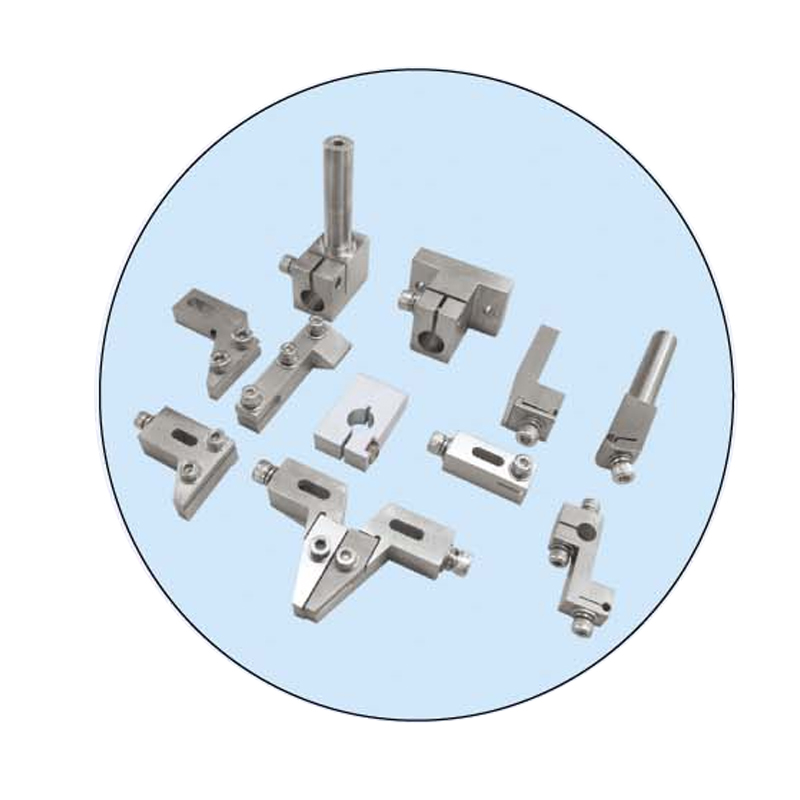

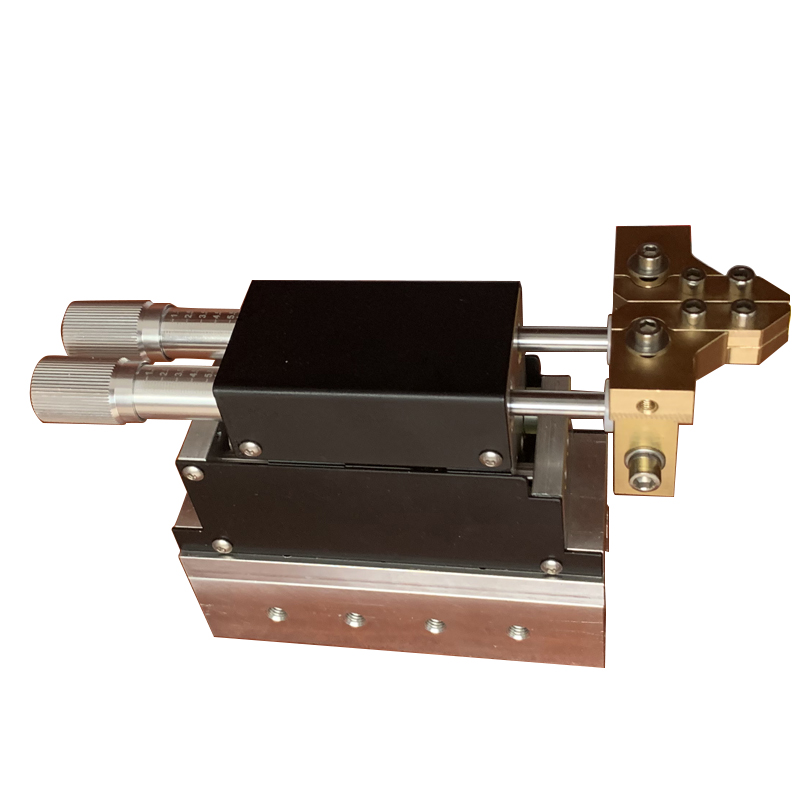

| XY Axis drive mode | Separate control of closed-loop stepper motor |

| Transmission mode | Imported linear guide rails and ball screws |

| Secondary spring pressurization | 0.5~5kgf |

| Equipment operation mode | Automatic continuous/single point/single step optional |

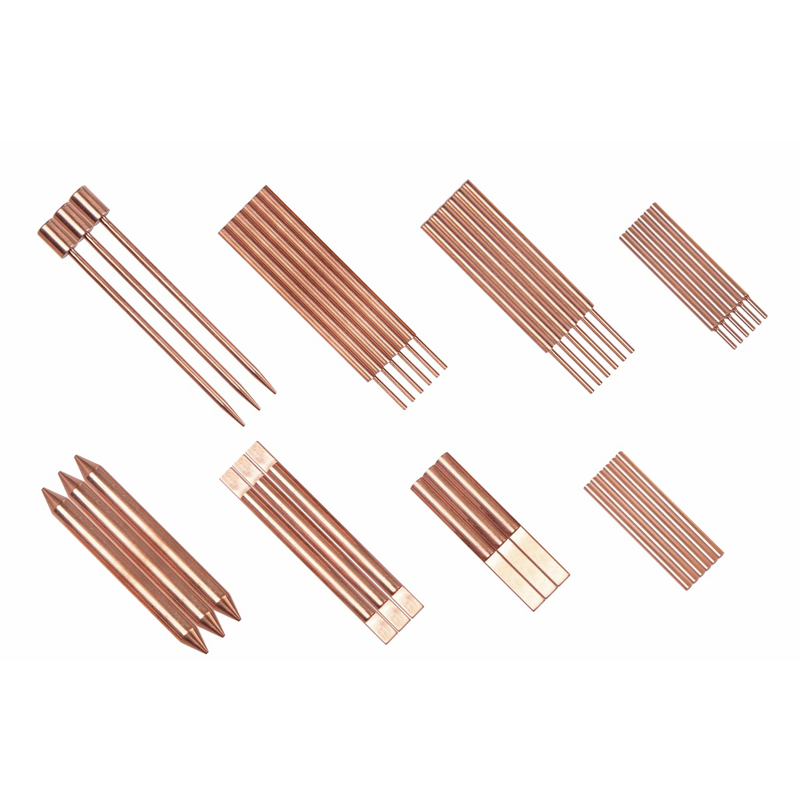

| Electrode material | φ3.0mm/φ2.0mm optional,imported aluminum oxide copper |

| Cooling method | Default natural air cooling,mandatory water cooling system optional |

| Position reciprocating accuracy | 0.02mm |

| Movement speed | 500mm/sec |

| Parameter storage | 99 sets |

| Platform load capacity | 60kg(Max.) |

| Welding power source | Compatible with imported and domestic welding power sources |

| Usage environment | ⑴Avoid using this equipment in places with high temperature, high humidity, vibration or impact, metal powder, and welding spatter. Pay attention to controlling the temperature of the surrounding environment of the equipment;⑵The equipment must be grounded and separated from the personnel grounding line |

| Size | 820×720×1300(L*W*H) |

| Weight | 100kg (Excluding power supply) |