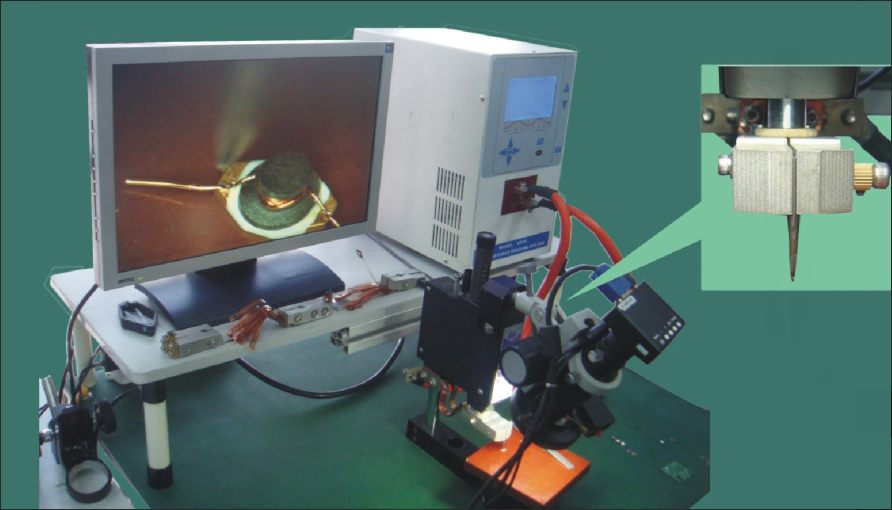

DC Resistance 2500A Spot Welding Equipments+WBT-F01 Mechanical Weldheads Micro precision Resistance Wire Weld machine

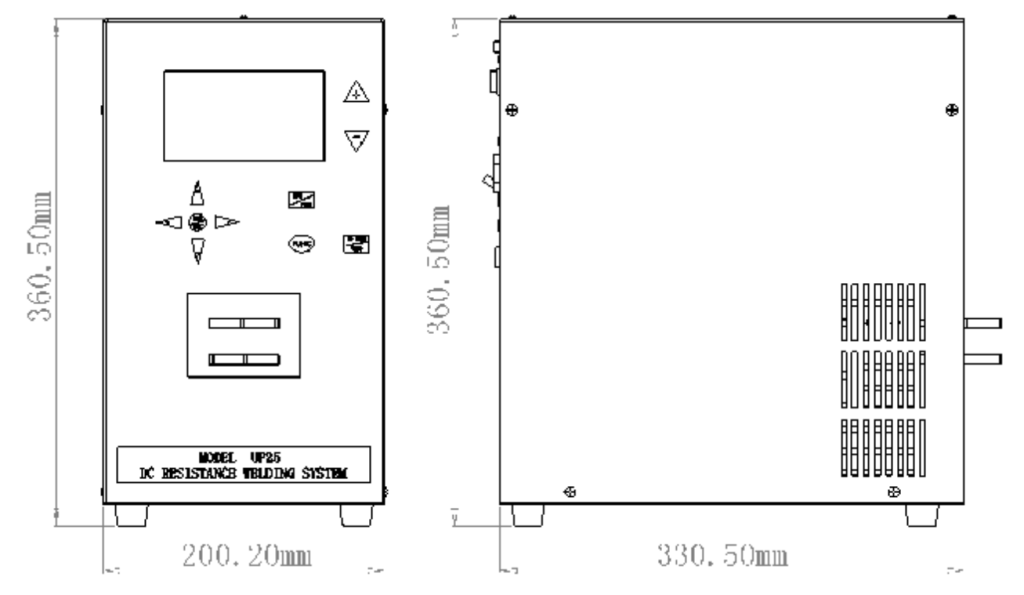

1.UF25 weld power supply

(DC resistence 2500A welding power supply)

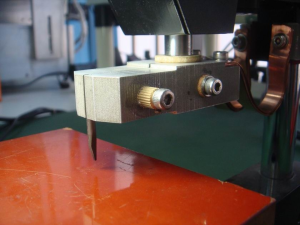

2.WBT-F01 single welding head

(Foot operated,net weight 10kg,348*193*430mm)

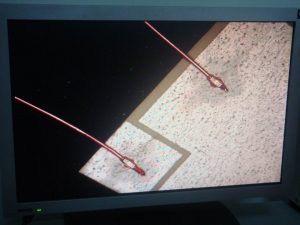

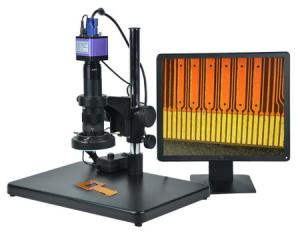

3.HD video microscope

4.Display screen

5.Power cables

6.Weld head switch connection cables

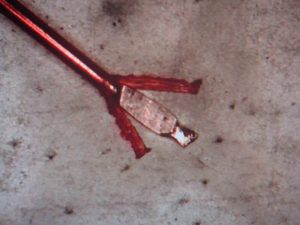

7.Needle type electrodes

8.Foot pedal

Product Details

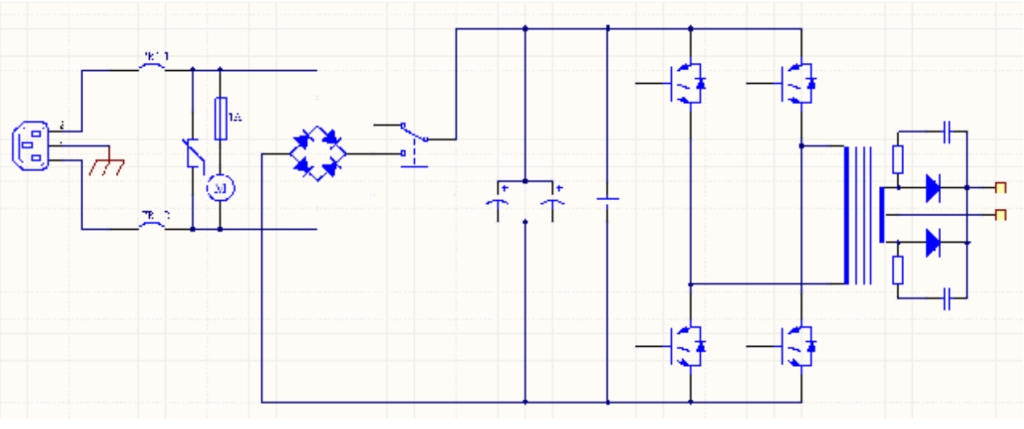

UF25 is a double pulse inverter DC welding power supply with excellent welding ability. The

main key components such as IGBT and ETA circuit breaker are imported from Germany to

ensure high quality. When welding the battery connector, it has the characteristics of short

welding time (millisecond level), low calorific value, little damage to the battery, good

appearance of the solder joint, high welding tensile strength, strong welding stability, high

control accuracy, and low welding defect rate.

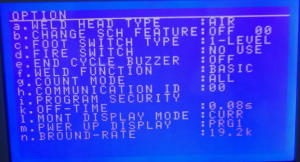

UF25 Feature introduction

High inverter frequency makes the control of welding energy more accurate and rapid.

With double pulse welding function.

Each pulse has the functions of slow rise, slow fall, welding time, welding energy and monitoring

data setting.

A variety of welding energy control modes, constant current / constant voltage / constant power,

to meet the welding needs of different shapes of materials.

Various welding working modes, ordinary spot welding, roll welding / seam welding, continuous

welding, double welding head control, PLC control.

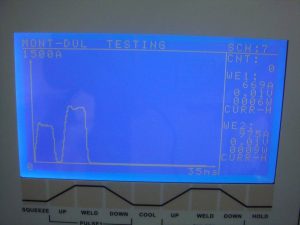

The welding results are displayed in text and graphics, which makes the debugging more intuitive

and simple.

It has the function of welding quality monitoring and result output, and automatically detects unqualified

products.

Serial communication function.

1.Parameter

Power supply: single phase, 220ACV/10A, Standby power consumption: 30W, maximum

welding current 2400A, Preloading time 0 ~ 999ms, preheating ramp 0 ~ 49 , pulse interval 0

~ 99ms , pressure maintaining time 0 ~ 999ms, Overall dimension (length: 200.2mm/ width:

360.5mm/ height: 330.5mm) , weight: 14.2kg

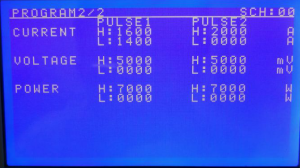

2.Three welding energy control modes, constant current / constant voltage / constant power,

meet the welding requirements of different shapes of materials.

(set welding current) Range 0~2400a, adjustment accuracy 1A.

(set welding voltage) The range is 0~5.00v, and the adjustment accuracy is 0.01V.

(set welding power) The range is 0~2500w, and the adjustment accuracy is 5W.

3.Five welding working modes, ordinary spot welding, roll welding / seam welding, continuous

welding, double welding head control, PLC control mode

General spot welding basic welding working mode:

used for general single point welding. The welding process can be set as single pulse or double

pulse as required, and all welding parameters and monitoring parameters are valid. The welding head

can use pneumatic, electric, or mechanical mechanisms.

Roll welding / seam welding working mode:

it is applicable to continuous welding on a single workpiece to make the welding points continuous

so as to form a weld. In this working mode, special seam welding head and corresponding welding

head controller must be used together. The pressure switch on the welding head or the welding head

controller can be used to control UF25 discharge welding.

Continuous welding mode:

it is applicable to the requirements of high-speed welding of multiple welding joints with the same

requirements. Using this working mode, the pneumatic welding machine head must be equipped with

a single-stage foot switch for welding control. The function of changing the specification cannot be used

in the welding process, and each welding specification can only be set as a single pulse.

Working mode of double welding heads:

one UF25 is matched with two pneumatic welding heads for single standard time-sharing single point welding.

This function effectively improves the use efficiency of UF25 and reduces the investment cost of equipment.

In this mode, a UF25 can be equipped with two sets of pneumatic welding heads, each of which needs a

pneumatic welding head, a discharge switch and a foot switch; Both sets of welding heads use the same

welding specification for time-sharing welding (only one set of welding mechanism works at the same time),

and single or double pulses can be used.

The PLC controller controls the working mode:

The UF25 is used as a separate welding power module, and its work is controlled by the main controller in the

automatic welding system, such as controlled discharge welding, controlled transformation of welding specifications,

feedback of welding results to the main controller and other functions. Due to the special interface with the upper

computer, the difficulty of uf25 embedding into the automation system is greatly reduced, and the working speed,

welding performance, quality monitoring and processing ability of the automation system can be effectively improved.

4.Welding quality monitoring and result output function, automatically detect unqualified products.

Description of welding monitoring parameter setting.

“Welding monitoring parameter setting” is used to set the parameters for monitoring and evaluating

the welding results, and is used for online detection of welding quality. This function evaluates the quality of each welding,

and then provides an alarm / prompt signal (on the input / output interface) for unqualified welding. It is a powerful tool

for quality monitoring and management in the production process.

5. Accuracy control of welding process and consistency of welding effect.

a.

UF25 DC inverter welding power supply, the core welding control components and modules adopt

European famous brands (non domestic), which is highly professional, and provides a guarantee

for the reliability and high accuracy of welding. It is not affected by the voltage fluctuation of the

power grid, the output current and voltage are stable, and the welding stability of batch products

is improved. LCD can intuitively display each welding waveform. If the welding parameters are

adjusted or a welding is unstable or unsatisfactory, the welding waveform will also display abnormally

for analysis and resetting. Domestic military enterprises, such as aerospace enterprises, also use our

inverter power supply and welding head. Our major domestic customers also use UF25/UF40 inverter

DC power supply to configure automatic welding equipment.

b.

Due to the excellent control of welding current output and welding time, when welding products, it

can achieve the effects of low calorific value of the workpiece, no yellowing and blackening of the

surface of the weldment, no splashing of sparks, and firm welding. Compared with energy storage

spot welding machine and AC machine, it is more suitable for precision welding of small workpieces.

c.

The welding pulse input slow rise and slow fall function of UF25, as well as the coordination of

the interval time and pressure holding time between the two pulses, carefully adjust the welding

parameters, and then match the good welding head and welding needle, which can make the

welding effect more perfect.

WBT-F01 Information

1.Size: 348 x 193 x 430mm

2.Weight: 10kg

3.Fire method: Micro switch

4.Electrode diameter:3mm/6mm

5.Weld pressure: 2.2—89N

6.Throat depth: 49mm

7.Driving method: by foot

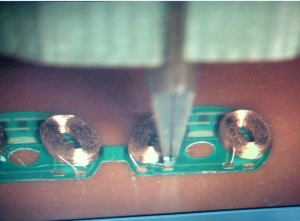

Needle type electrodes

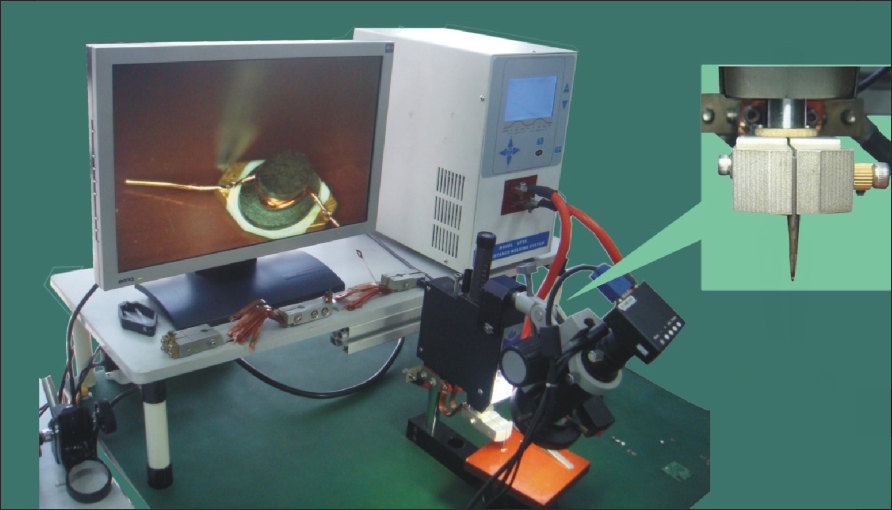

CCT+display screen

UF25 details information

Setting the welding parameter

Weld monitor

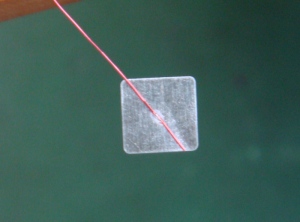

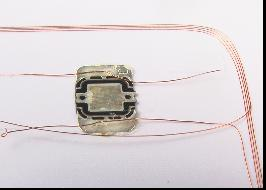

Application

Company photos